Graphic Engineering

Engineers to the Print Finishing Industry

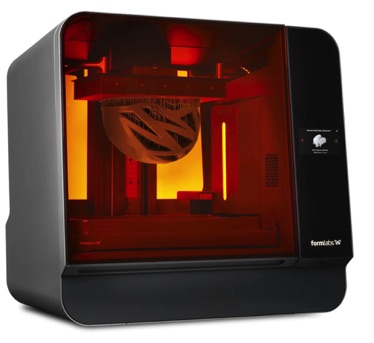

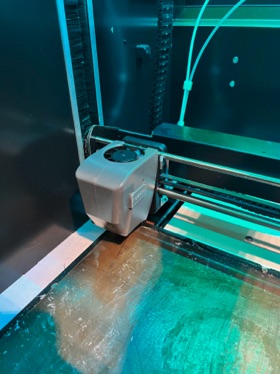

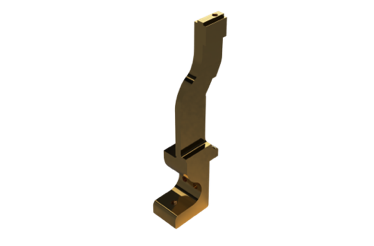

3D Printing

Over the years 3d printing has moved from badly printed parts with lines and lamination, in plastics that did not have the physical properties for industrial use. We can make parts now with great accuracy, in plastics that are industrial and with a finish that can be hard to tell if it is 3d printed or injection moulded.